About KTIS

Vision

KTIS Group is a leading organization with an outstanding world-class identity. It has maintained good governance, integrated closely with agricultural and industrial industry, maintained social awareness, added values and quality to sugar and its by products, and utilized clean and eco-friendly energy to sustain stability.

Mission

- The company operates its businesses with keen knowledge and experiences, creative ideas and professionalism in order to generate innovation and value to its products and services ranging from upstream to downstream.

- The company creates a sustainable source of raw materials in order to support a fully integrated business network for the production of high-quality products as well as the generation of clean and eco-friendly biomass energy.

- The company conducts its business with high ethics and integrity while maintaining good governance in both existing and new business investments for valuable return in both financial and non-financial forms back to the community, investors, customers, employees, farmers and stakeholders.

57+ YEARS OF EXPERIENCE

Our Business

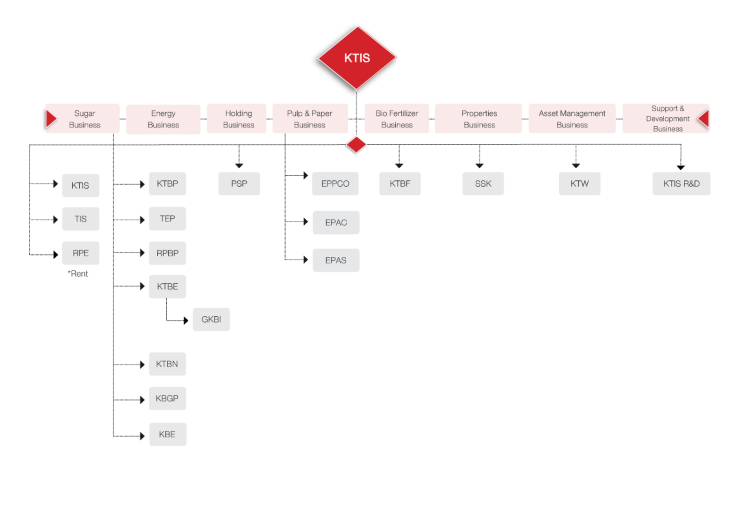

Fully Integrated Business

The manufacturing process of sugar from sugarcane is a process that yields various by-products. KTIS Group has invested in an integrated industrial business with the objective to be resourceful. For example, investing in a factory producing paper pulp from bagasse, ethanol from molasses, and a biomass power plant using bagasse from sugar mills as a raw material. In addition, the business has been designed to add value to various raw materials in the business networks without depending on external sources, which results in business stability and low risk in raw material shortage.

At the KTIS Complex, where factories of KTIS Group are located, the manufacturing process has been designed as evolving the process from the core production of Kaset Thai factory to other related industrial factories, such as bagasse transportation with conveyor, or molasses transportation via pipeline, rather than transportation by trucks which requires a lot of fuel, in order to reduce the cost of transporting raw materials as well as conserve energy.

KTIS Complex is also ready to support the expansion of other related industrial factories, which will use by-products from the manufacturing process as raw materials, in order to enhance further products in the future.

Meet Our Management Team

Mr. Parphan Siriviriyakul

Chief Executive Officer and Chief Executive Officer – KTIS Group

Mr. Sirapak Siriviriyakul

Director and Chief Financial Officer – KTIS Group

Dr. Darat Siriviriyakul Vibhatakalasa

Deputy Chief Executive Officer – KTIS Group

Mr. Prasert Siriviriyakul

Deputy Chief Executive Officer – KTIS Group

Mr. Nathapun Siriviriyakul

Deputy Chief Executive Officer – KTIS Group